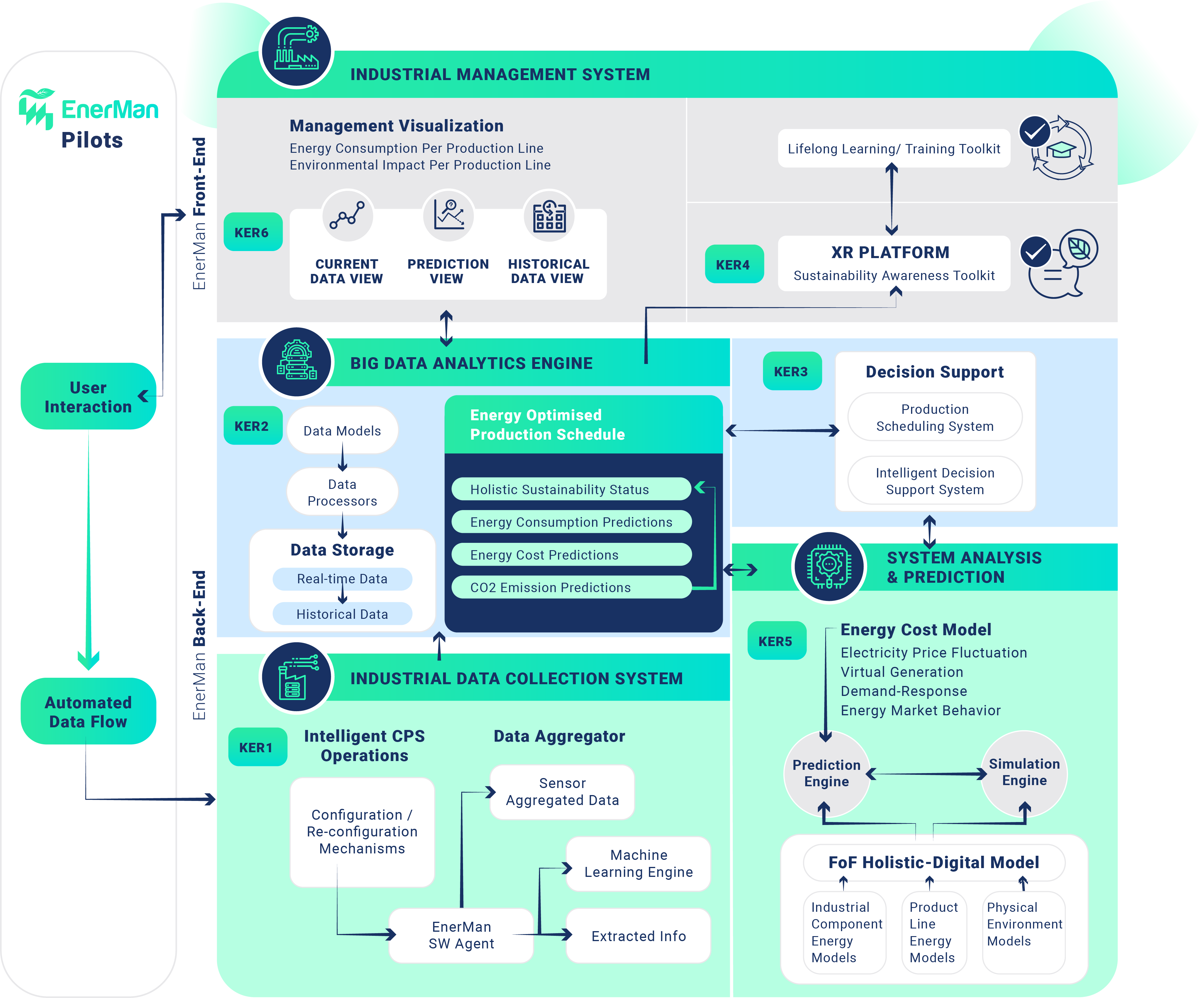

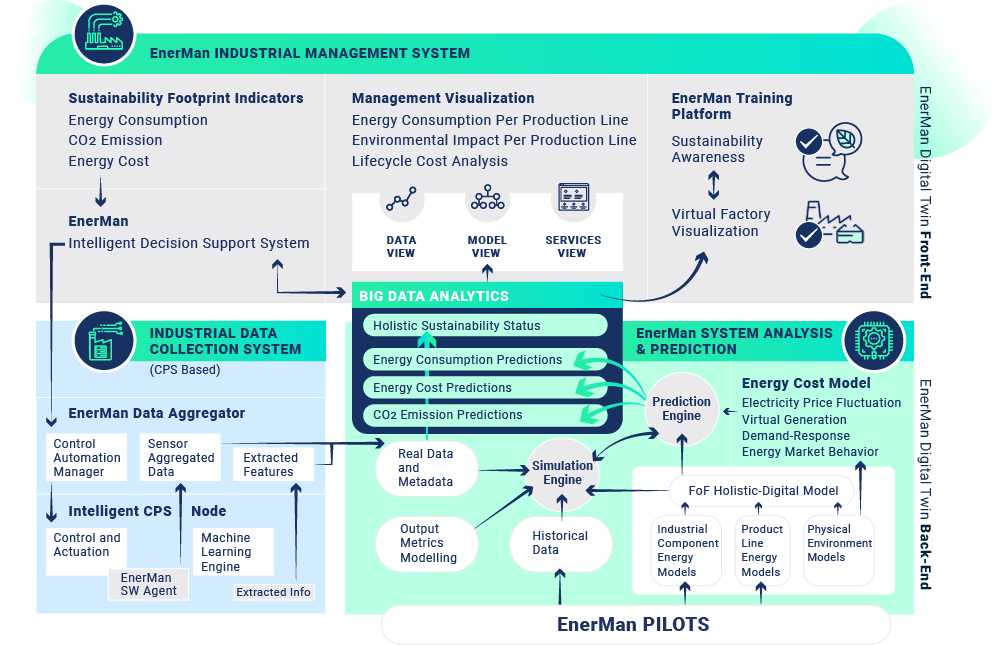

We envision the EnerMan solution as a framework that spans throughout the whole design operation continuum of a smart factory industrial manufacturing so that makes it adaptable to achievable energy sustainability indicators, by predicting the energy consumption when changes in the overall factory value chain/production lines and processes appear in the future are made or when the external cost conditions of the provided energy fluctuates (due to variations in the energy production market) and then provide autonomously updates in the factory production line, equipment, processes control loop.

In parallel, the EnerMan system aims to train factory users and administrators on achieving through good practises energy sustainability. The EnerMan framework aims at addressing the above goals in a systemic, holistic way, collecting and processing real data from multiple manufacturing sources, as well as generating data from simulation to extract energy prediction results. In EnerMan we consider in the adaptation process a plethora of factors that affect a factory energy sustainability footprint like production line and equipment consumption, human factor activities, energy provider cost variations (change in the cost of the 1kWh during a day) as well as machinery long term malfunctions that may influence their energy consumption. Our overall goal is to create a complete framework that can assess the energy sustainability of a factory and autonomously, flexibly adapt the control management of a factory’s various manufacturing processes (eg. closed control loops) in a cognitive way so that the systemic energy consumption is minimized, and the factory environmental footprint is reduced.

This project received funding from the European Union’s Horizon 2020 Research and Innovation program under Grant Agreement n° 958478

This project received funding from the European Union’s Horizon 2020 Research and Innovation program under Grant Agreement n° 958478

Get more Information: https://cordis.europa.eu/project/id/958478

Copyright © 2021, EnerMan Project - Horizon 2020, All Rights Reserved. Site by Intract.